Cooling pad

|  |  |

| Brown | Green | Black |

| specifications | 7090 | 6090 | 5090 |

| Ripple Height | 7mm | 6mm | 5mm |

| Ripple angle | 45*45 | 45*45 | 45*45 |

| Height£¨mm£© | 1500,1800,2000 | 1500,1800,2000 | 1500,1800,2000 |

| Width£¨mm£© | 600,300,200 | 600,300,200 | 600,300,200 |

| Thickness£¨mm£© | 300,200,150,100 | 300,200,150,100 | 300,200,150,100 |

Cooling Pad, or called wet pad, made of hydroscopicity kraft paper, is mainly used for the cooling system, humidification system and filter system. Mainly through the surrounding water evaporation cooling air, water vapor, regulating the air humidity, water vapor adsorption of dust smoke particles in the air to adjust the temperature, air humidity, air purification, widely used for livestock and poultry house ventilation ventilation cooling in summer. Rational design of the damp curtain ventilator installed cooling and ventilation system, can make the air inside the animal house fresh and cool and comfortable, avoid high temperature air circulation caused by viruses grow, leading to the collective mass of infected poultry or even death, ensure safe and efficient production.

Good raw materials + rigorous process + elaborate + sincere service, is our great company always adhere to the "quality first" as the core to participate in market competition weight. GLITTER high-end wet curtain, compared to the domestic market the general quality of the wet curtain has the advantages of high evaporation efficiency, corrosion resistance, mildew resistant, long life characteristics. Select the GLITTER high-end damp curtain ventilator cooling ventilation system, is to choose the health, environmental protection, high efficiency and energy saving cooling and ventilation of a good helper.

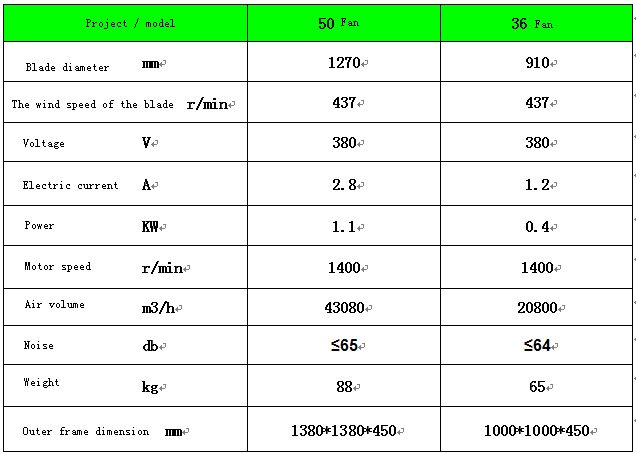

High end fan

Chrysanthemum fan

A. chrysanthemum fan 6 fan blades is through computer data production model, using Krupp self-cleaning stainless steel material by abrasive stamping molding, each fan blade are measured by the static balance of the heavy, fan blade structure of each fan through dynamic balancing machine dynamic balance calibration, dynamic balance quantity control within 1g, to reach the highest level of international same profession. Chrysanthemum fan fan blade structure design ensures that the high strength, high air volume, low noise, the use of ten years air reduction, is the embodiment of technology research personnel of the company in the field of power fan.

B. fan frame structure through the strength test design, production using domestic large steel mills 270G one-time punch forming ultra thick galvanized steel and high strength; using standard fastening piece for electric and pneumatic tools pipelining assembly, can effectively protect the fan from being damaged. Galvanized galvanized layer of super thick ensures fan surface appearance and durability.

C. chrysanthemum fan increases the fan handle humanization design, avoids in the handling and transportation process of inconvenient installation, structure of concave hole makes the fan does not will handle mounted to the wall in the damaged in and affect the overall appearance of the fan.

D. mechanical centrifugal open mechanism adopts the toughness reinforced nylon 100% material injection molding processing of high strength, long service life; the guide rod embedded steel member is arranged on the flange plate, enhances the reliability of the mechanism; rotating structure with internal bearing makes the opening mechanism of flexible rotation. When turning in the wind turbine, centrifugal force hammer produced and connecting structure reliable makes opening mechanism can quickly and flexibly be the louver sheet away.

Louver structure E. chrysanthemum fan when the fan is not running tight closure, can effectively block of homes wind and light to enter the shed. The middle of shutter blade made of galvanized plate stamping thickened and. Plastic linkage shutter sheets have opened by adding anti, anti aging agent oil all plastic processing, good lubrication, long life.

F. uses a V type triangular quality belt, high strength, long service life, convenient maintenance, replacement. The degree of tightness of triangle belt to the index finger and middle finger in the triangle zone of central pressure 15~20mm is the most suitable.

Using the brand motor well-known manufacturers, IP54 standard protection grade and F grade insulation level, so that more reliable wind machine. In the hot summer, when the wind machine running continuously without worry and worry about motor strike.

G. flange, belt wheel and the wheels are made of high strength aluminum magnesium alloy die casting manufacturing, good corrosion resistance. Waterproof design special, so that water can not enter the bearings

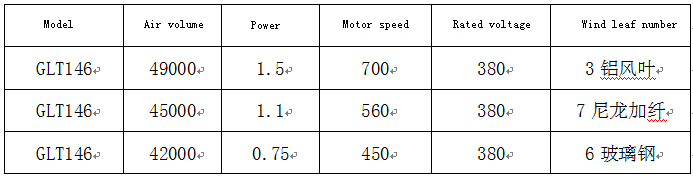

Glass steel anti-corrosion fan

A. frame material for the FRP high strength steel, having anti ultraviolet ray, acid and alkali resistance, anti-corrosion rust. The use of unique shape design of diversion, increase the flow effect, waterproof. Integrated molding, excluding metal combination, resonate.

B.: direct drive structure design, high efficiency, free repair. Direct type noise and belt without traditional belt type transmission fan, gear change problems. Can be used continuously for 100 days (2400 hours).

C. fan structure: direct design and Germany, Netherlands, Italy and other countries synchronization.

D. motor: by the Taiwan professional design, R & D, manufacturing, warranty for three years. Miniaturization design of lightweight (aluminum alloy) strong quiet, fast heat dissipation. Explosion proof grade "IP55" level of protection.

E. shutter for the production of PVC raw materials, good quality and beautiful.

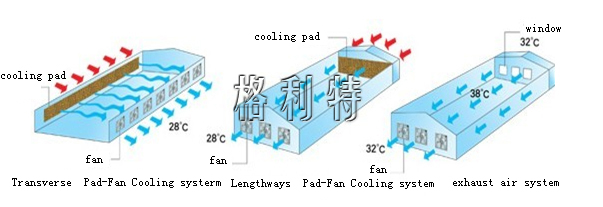

Cooling system

|  |  |

| Cooling system | High strength aluminum alloy frame | 7090The high-end wet curtain |

Leveraging the principle of heat absorption though evaporation and exhaust fan.Glitter Pad-Fan Cooling Systerm proves to eliminate waste gas reduce the temperature ,thus environment and keeping cool and favourite air .¡°Pad-Fan Cooling Systerm¡±is the best economiical and effective option for cooling in the summer.

Glitter Pad-Fan is mainly composed of water pad wall and exhaust fan.

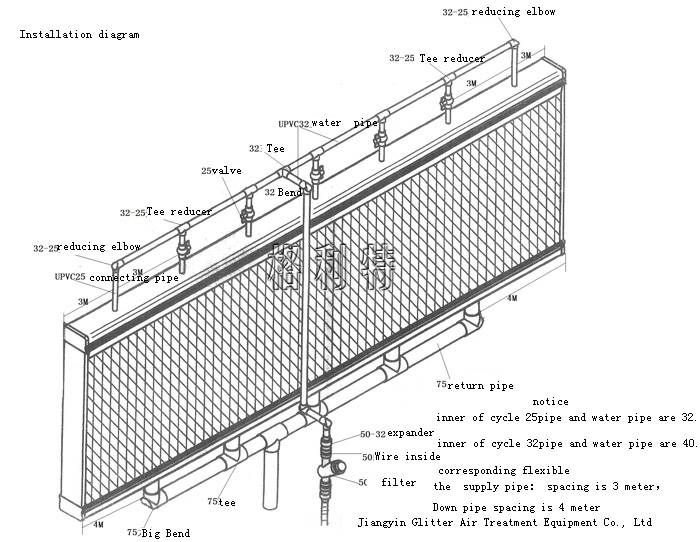

Water pad wall.Consists of aluminum alloy frame ,cooling pad ,inner components of the frame.

Aluminum alloy framework is used for fixing the cooling pad and ensuring the water cycle of the pad surface.It is made through the special aluminum alloy mould.It boasts a few properties. Such as easy installation,high strength,corrosion resistance ,compact structure .No leaking and so on.

Glitter Cooling Pad is the core of the cooling system .It is high spreading speed .Long efficiency,safe and no pollution.Due to the environment ,energy-saving and economical properties,it is a good choice among the cooling products.

Inner components of the frame. : the use of UPVC pipe fittings, high quality of high strength, good cold resistance, ensure that the water in the wet curtain surface circulation use.

Installation design

1,The wet curtain arrangement should try to reduce the ventilation to ensure indoor ventilation even dead.

2, The design of the wet curtain system should according to the site of summer light and wind consider installing position.

3,The wet curtain adopts embedded type installation, smooth opening around surface treatment and on eaves reserved space for installation.

4, The wet curtain adopts plug-in installation required civil party shall be prefabricated fixings.

5, The wet curtain paper only lateral assembly ,in no case shall avoid impeding the flow of vertical assembly.

6,When the wet curtain with the fan suction is used ,space ventilation window and other openingsare airtight.

7, The wet curtain with fan positive pressure when in use, the need for a separate design installation scheme according to the construction drawings and use requirements.

8, Water supply is generally appropriate to increase the wet curtain in foundation design of the water supply volume of drying, high temperature area..

The system use and maintenance

1,The reservoir shall be stamped with the sun and dust, conditional when wet curtain should also do the appropriate shading.

2, When the temperature is below 5 degrees, do not use wet curtain system, avoid impeding airflow, freezing water pipe.

3,When the wet curtain top seal, do not allow the operation of wet curtain system, do not use wet curtain long time should be whole sealing barrier.

4, Befor turning off the water system, the exhaust fan must remain rotating more than 30 minutes till the cooling pad absolutely dry.

5, It should be regularly (weekly) cleaning tank, ensure the cycle water PH keep 6~9and conductivity less than 1000 micromhos.

6, The wet curtain bottom can not have long-term immersion in water in case the algas breeding

7, When the wet curtain surface algae breeding can put 3 - 5ppm to the pool chlorine or bromine, continuous treatment concentration was 1ppm.

8, The wet curtain operation must ensure the water supply pipe the water evenly, the filter needs cleaning regularly (weekly).

The other explanation

1, The wet curtain paper and wet curtain frame should generally be assembled at the project site, avoid transportation bump.

2, When the size of houses for civil construction error opening party beyond the design error wet curtain scheme, can be fine tuned in assembly.

3, Wet curtain cooling effect depends on the performance of the fan , Confined space and Outdoor air humidity.

4,The general should provide the wet curtain system of water pump, electric wire, power distribution boxes and other equipment .

5, the water supply quantity to adjust through the pump selection or valves, visual effect is ideal water for the whole of the wet curtain without the drenched dry streaks, also can see the thin water flowing down along the ripple.

6, Before transported to the construction site for installation, the wet curtain paper shall kept attention to fire prevention. due to the flammable.

7, Wet curtain system extended change significantly with age.

Wet curtain system based on the correct installation and regular maintenance, the service life of the whole 5 years (artificial damage, transport damage, water quality reasons, other natural disasters except).

Engineering case